![[content:title]](/static/upload/image/20241007/1728271957403212.jpg)

Spring steel wire is a metal wire specially used for making springs. It has high strength, good elasticity, excellent toughness and fatigue resistance. It is widely used in mechanical fields such as automobile suspension systems and industrial machinery, as well as in electronic appliances and household items. The manufacturing process usually involves wire drawing and may include heat treatment to enhance its properties.

I. Introduction

Spring steel wires, as an important industrial material, play a crucial role in fields such as mechanical manufacturing, the automotive industry, and electronic equipment. American and German standard spring steel wires are highly regarded for their strict quality standards, excellent performance, and wide range of applications. This article will provide a detailed description of the materials, chemical compositions, mechanical properties, and uses in various fields of American and German standard spring steel wires, demonstrating their important value in modern industry.

II. American Standard Spring Steel Wires

1. ASTM 9255

- Material Composition: The chemical composition of ASTM 9255 spring steel wire is carefully designed to ensure excellent performance. It usually contains a relatively high proportion of carbon, which gives the wire high strength and hardness. At the same time, it contains an appropriate amount of manganese, silicon, and other elements, which help improve the toughness and processability of the wire. In addition, the content of impurity elements such as sulfur and phosphorus is strictly controlled to ensure the quality and reliability of the wire.

- Mechanical Properties: This spring steel wire has outstanding mechanical properties. Its yield strength is usually above 1127 MPa, and its tensile strength can reach 1274 MPa, showing an extremely high strength level. The elongation can also reach more than 10%, indicating that it still has certain ductility when subjected to large stresses. In addition, ASTM 9255 spring steel wire also has good fatigue strength and can maintain stable performance under repeated stress.

- Uses: Due to its excellent performance, ASTM 9255 spring steel wire is widely used in multiple fields. In the automotive manufacturing industry, it can be used to manufacture key components such as engine valve springs and suspension system springs to ensure the stability and comfort of cars under various road conditions. In the metal products industry, it can be used to manufacture various high-strength springs, such as die springs and stamping springs. In the field of household appliances, spring components in equipment such as washing machines and refrigerators often use this spring steel wire. In addition, it is also widely used in fields such as mechanical manufacturing and food machinery.

2. ASTM A228/A228M Music Wire

- Material Composition: ASTM A228/A228M music wire is famous for its high-quality material. It has a moderate carbon content and is combined with an appropriate amount of manganese, silicon, and other elements, making the wire have good elasticity and toughness. The chemical composition of this wire is controlled very precisely to ensure its high-performance performance in the music field and precision instruments.

- Mechanical Properties: Music wire has extremely high tensile strength and elastic limit and can withstand large tensile stresses without permanent deformation. Its fatigue strength is also very excellent and can maintain stable performance under repeated bending and stretching. In addition, music wire has a relatively high elastic modulus, which enables it to quickly return to its original state after being stressed and provides accurate elastic support for musical instruments and precision instruments.

- Uses: Mainly used in fields where spring performance requirements are extremely high. In instrument manufacturing, such as piano and violin strings and spring components often use music wire. Its excellent elasticity and sound quality performance enable musical instruments to emit beautiful sounds. In the field of precision instruments, spring elements in equipment such as measuring instruments and clocks also rely on the application of music wire, which can provide accurate elastic control and stable performance for these devices.

3. ASTM A401

- Material Composition: ASTM A401 spring steel wire belongs to chromium-silicon alloy spring steel wire and contains chromium, silicon and other alloying elements. The addition of chromium elements improves the corrosion resistance and oxidation resistance of the wire, and silicon elements help improve the strength and elasticity of the wire. In addition, it contains an appropriate amount of other elements to optimize the performance of the wire.

- Mechanical Properties: This spring steel wire has good elasticity, relatively high strength and excellent fatigue resistance. It can maintain stable performance at higher temperatures and is suitable for some spring applications that work in high-temperature environments. Its yield strength and tensile strength are moderate and can meet the needs of different fields.

- Uses: Widely used in fields such as automobiles, household appliances, and precision electronics. In automobile engines, components such as valve springs and fuel injector springs often use ASTM A401 spring steel wire to ensure the normal operation of the engine. In household appliances such as air conditioners and microwave ovens, spring elements also use this wire. In the field of precision electronics, some small springs and elastic elements also choose ASTM A401 spring steel wire to ensure the accuracy and reliability of the equipment.

III. German Standard Spring Steel Wires

1. 50CrV

- Material Composition: In the chemical composition of 50CrV spring steel wire, the carbon content is between 0.46% and 0.54%, the silicon content is between 0.17% and 0.37%, the manganese content is between 0.50% and 0.80%, the chromium content is between 0.80% and 1.10%, and it also contains a certain amount of vanadium element (0.10% - 0.20%). The reasonable combination of these elements makes the wire have high strength, toughness and fatigue strength.

- Mechanical Properties: 50CrV spring steel wire has high fatigue strength and yield ratio. After heat treatment, its strength and toughness are further improved. The hardness in the hot-rolled state is ≤321HB, and the hardness after cold drawing + heat treatment is also ≤321HB. The elongation δ5(%) is ≥10, and the reduction of area ψ(%) is ≥40, indicating that it has good ductility when stressed.

- Uses: Mainly used for manufacturing important springs with large cross-sections and valve springs, piston springs, safety valve springs, etc. that work at temperatures below 300°C. It plays an important role in fields such as mechanical manufacturing and the automotive industry and provides reliable elastic support for various equipment.

2. 54SiCr6

- Material Composition: 54SiCr6 spring steel wire mainly contains silicon, chromium and other elements. The content of silicon element is relatively high, which helps improve the elasticity and strength of the wire. Chromium element can improve the corrosion resistance and oxidation resistance of the wire.

- Mechanical Properties: This spring steel wire has high elasticity, high strength and good toughness. It can withstand large stresses without permanent deformation, and can still maintain stable performance under repeated stress.

- Uses: Commonly used in spring manufacturing in fields such as automobiles, mechanical manufacturing, and precision electronics. For example, springs in automobile suspension systems, springs in mechanical tools, and elastic elements in precision electronic equipment can all use 54SiCr6 spring steel wire.

3. T9A

- Material Composition: The carbon content of T9A spring steel wire is between 0.85% and 0.94%, the silicon content is ≤0.35%, the manganese content is ≤0.40%, the sulfur content is ≤0.020%, and the phosphorus content is ≤0.030%. The characteristics of its chemical composition determine that it has high hardness and certain toughness.

- Mechanical Properties: The hardness of T9A spring steel wire is relatively high. After quenching treatment, the hardness can reach ≥62HRC. In the annealed state, the hardness is ≤192HB, and the indentation diameter is ≥4.35mm. Although its impact resistance is relatively weak, it still has wide applications in some occasions where high hardness is required.

- Uses: Mainly used for manufacturing tools with relatively high hardness and certain toughness but not subject to severe vibration and impact, such as center mills, punches, punch heads, wood cutting tools, blades for feed machines, chisels for drilling rocks, and other tools. In some specific spring applications, T9A spring steel wire can also be selected according to needs.

IV. Advantages of American and German Standard Spring Steel Wires

1. Strict quality standards: American and German standard spring steel wires follow strict quality standards and strictly control aspects such as chemical composition, mechanical properties, and dimensional accuracy. This ensures the stable and reliable quality of spring steel wires and can meet the requirements of various complex applications.

2. Excellent performance: Whether it is high strength, high elasticity, good corrosion resistance and oxidation resistance, American and German standard spring steel wires have excellent performance. These performances enable them to maintain stable performance in different working environments and extend the service life of springs.

3. Wide range of application fields: Due to their excellent performance, American and German standard spring steel wires can be applied in multiple fields such as automobiles, mechanical manufacturing, electronic equipment, and instrument manufacturing. Whether in high temperature, high pressure or harsh corrosive environments, suitable spring steel wire products can be found.

4. Technological innovation: American and German standard spring steel wire manufacturers continuously carry out technological innovation and develop new materials and production processes to improve the performance and quality of spring steel wires. This enables them to maintain competitiveness in the market and provide users with better products and services.

V. Conclusion

American and German standard spring steel wires have become indispensable materials in modern industry due to their strict quality standards, excellent performance, and wide range of application fields. Through a detailed introduction to their material composition, mechanical properties, and uses in various fields, we can see that they play an important role in various fields. Whether in automotive manufacturing, mechanical manufacturing or electronic equipment, American and German standard spring steel wires provide reliable guarantees for the performance and quality of products. With the continuous progress of technology and the continuous growth of market demand, it is believed that American and German standard spring steel wires will continue to play an important role in the future and make greater contributions to the development of various industries.

QUALITY INSPECTION

We have won many stable customers with our excellent quality and good service. The company's products are subject to third-party testing. We hope you can become one of our good customers. Please feel free to contact us.

PACKING AND SHIPPING

In order for the products to arrive safely, we choose sturdy sea-resistant packaging or according to your needs. Professional and sturdy packaging to protect plates, coils, profiles, bars, pipes, wire rods etc. to the greatest extent and avoid bumps and scratches during transportation.

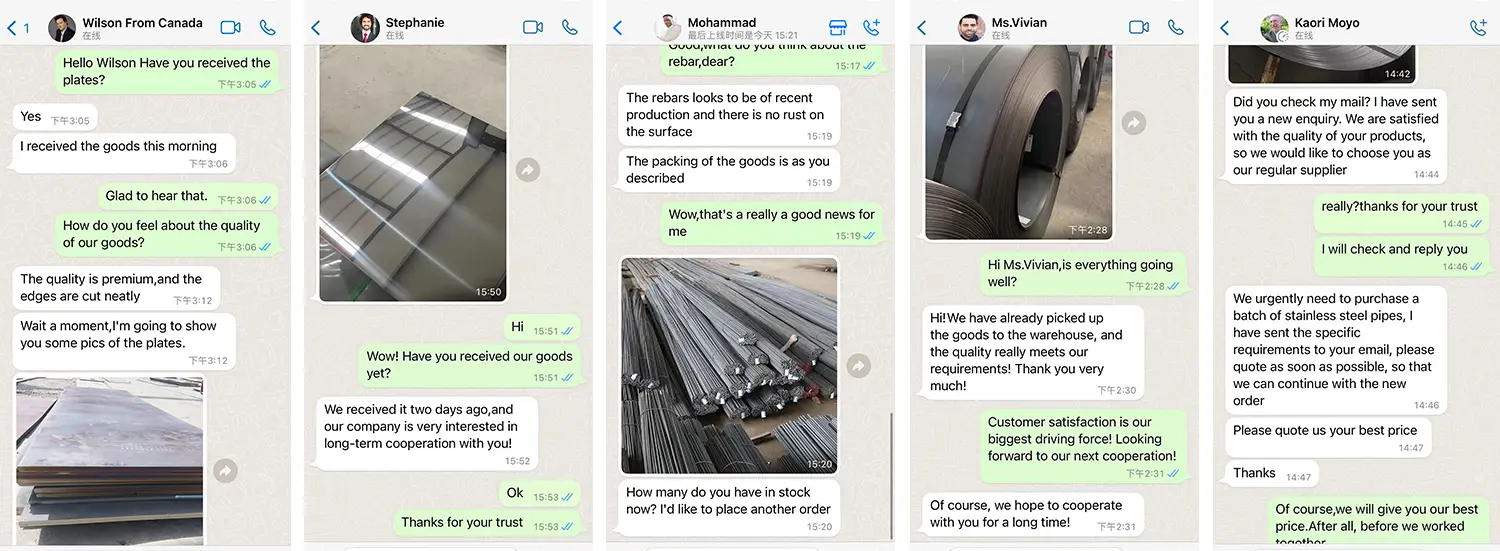

CUSTOMER FEEDBACK

We can provide one-stop services, including transportation, customs clearance and insurance, so that you can handle logistics matters more easily.

Products that are being sold at low prices We will deal with a batch of extruded inventory at ultra-low prices from time to time. The products we deal with include steel pipes, steel plates, round bars, steel bars, steel coils, profiles, rails, wires, etc. Our purpose in dealing with inventory at low prices is to quickly monetize the goods for our daily expenses of steel production. Low-priced products are given priority to regular customers. If you are interested in low-priced steel, please contact us quickly.