![[content:title]](/static/upload/image/20241010/1728546671879625.jpg)

For 304 stainless steel plate:

- Widely used in household items such as tableware and kitchenware. Due to its good corrosion resistance and processing performance, it is durable and easy to clean.

- Also common in architectural decoration, used for making doors, windows, railings and other fixtures. It has an aesthetic appearance and can adapt to various weather conditions.

For 316 stainless steel plate:

- Because of its stronger corrosion resistance, especially resistance to seawater corrosion, it is often used in equipment and structures in marine environments, such as ship accessories and offshore oil platform facilities.

- In industries such as chemical and medical that have extremely high material requirements, it is used to manufacture containers and pipelines for storing and transporting corrosive media.

For 321 stainless steel plate:

- Suitable for use in high-temperature environments. For example, in aerospace, petrochemical and other high-temperature process equipment, it can withstand certain high temperatures without deformation or damage.

- Also used to manufacture furnace components that need to resist high-temperature oxidation.

Here is an introduction to the chemical composition content data, performance data, and application fields and uses of all stainless steel round bar materials of American, European, and Japanese standards:

I. American Standard Stainless Steel Round Bars

1. 304 Stainless Steel Round Bar:

- Chemical Composition: Carbon (C) ≤0.08%, Silicon (Si) ≤1.00%, Manganese (Mn) ≤2.00%, Phosphorus (P) ≤0.045%, Sulfur (S) ≤0.030%, Chromium (Cr) 18.00% - 20.00%, Nickel (Ni) 8.00% - 10.50%.

- Performance Data: With a density of 7.93 g/cm³, tensile strength ≥515 MPa, yield strength ≥205 MPa, and elongation ≥40%. It has good corrosion resistance, processing performance, and welding performance, and can withstand high temperatures up to 800°C.

- Application Fields: Widely used in the food processing, chemical, building decoration, and medical device industries. For example, it is used to make food processing equipment, chemical containers, building structural parts, and surgical instruments.

2. 316 Stainless Steel Round Bar:

- Chemical Composition: Carbon (C) ≤0.03%, Silicon (Si) ≤1.00%, Manganese (Mn) ≤2.00%, Phosphorus (P) ≤0.045%, Sulfur (S) ≤0.030%, Chromium (Cr) 16.00% - 18.00%, Nickel (Ni) 10.00% - 14.00%, Molybdenum (Mo) 2.00% - 3.00%.

- Performance Data: With a density of 7.98 g/cm³, tensile strength ≥515 MPa, yield strength ≥205 MPa, and elongation ≥40%. It has excellent corrosion resistance, especially in marine environments and chloride-containing media, and also has good high-temperature resistance.

- Application Fields: Commonly used in marine engineering, chemical, medical device, and pharmaceutical fields. Such as manufacturing marine platform structural parts, chemical pipelines, medical device components, and pharmaceutical equipment.

II. European Standard Stainless Steel Round Bars

1. 1.4301 Stainless Steel Round Bar (equivalent to American standard 304):

- Chemical Composition: Carbon (C) ≤0.07%, Silicon (Si) ≤1.00%, Manganese (Mn) ≤2.00%, Phosphorus (P) ≤0.045%, Sulfur (S) ≤0.030%, Chromium (Cr) 17.50% - 19.50%, Nickel (Ni) 8.00% - 10.50%.

- Performance Data: With a density of 7.93 g/cm³, tensile strength ≥520 MPa, yield strength ≥210 MPa, and elongation ≥40%. It has good corrosion resistance, processing performance, and welding performance.

- Application Fields: Widely used in building decoration, kitchen equipment, food processing, and chemical equipment fields. Similar to American standard 304, it can be used to make various structural parts, containers, and pipelines.

2. 1.4404 Stainless Steel Round Bar:

- Chemical Composition: Carbon (C) ≤0.03%, Silicon (Si) ≤1.00%, Manganese (Mn) ≤2.00%, Phosphorus (P) ≤0.045%, Sulfur (S) ≤0.030%, Chromium (Cr) 16.50% - 18.50%, Nickel (Ni) 10.50% - 13.00%, Molybdenum (Mo) 2.50% - 3.00%, Nitrogen (N) ≤0.11%.

- Performance Data: With a density of 7.98 g/cm³, tensile strength ≥520 MPa, yield strength ≥210 MPa, and elongation ≥40%. It has excellent corrosion resistance, especially good corrosion resistance to various organic acids, inorganic acids, alkalis, and salts, and also has good resistance to sensitized intergranular corrosion.

- Application Fields: Mainly used in the chemical, petroleum, pharmaceutical, and food processing industries. For example, manufacturing chemical equipment, petroleum pipelines, pharmaceutical machinery, and food processing equipment.

III. Japanese Standard Stainless Steel Round Bars

1. SUS304 Stainless Steel Round Bar:

- Chemical Composition: Carbon (C) ≤0.08%, Silicon (Si) ≤1.00%, Manganese (Mn) ≤2.00%, Phosphorus (P) ≤0.045%, Sulfur (S) ≤0.030%, Chromium (Cr) 18.00% - 20.00%, Nickel (Ni) 8.00% - 10.50%.

- Performance Data: With a density of 7.93 g/cm³, tensile strength ≥520 MPa, yield strength ≥205 MPa, and elongation ≥40%. It has good corrosion resistance, processing performance, and welding performance.

- Application Fields: Widely used in household products, automotive parts, medical devices, building materials, and food industries. For example, making tableware, automotive parts, medical devices, and building structural parts.

2. SUS316 Stainless Steel Round Bar:

- Chemical Composition: Carbon (C) ≤0.08%, Silicon (Si) ≤1.00%, Manganese (Mn) ≤2.00%, Phosphorus (P) ≤0.045%, Sulfur (S) ≤0.030%, Chromium (Cr) 16.00% - 18.00%, Nickel (Ni) 10.00% - 14.00%, Molybdenum (Mo) 2.00% - 3.00%.

- Performance Data: With a density of 7.98 g/cm³, tensile strength ≥520 MPa, yield strength ≥205 MPa, and elongation ≥40%. It has excellent corrosion resistance, especially in marine environments and chloride-containing media.

- Application Fields: Mainly used in marine engineering, chemical, medical device, and pharmaceutical fields. Such as manufacturing marine platform structural parts, chemical pipelines, medical device components, and pharmaceutical equipment.

QUALITY INSPECTION

QUALITY INSPECTION

We have won many stable customers with our excellent quality and good service. The company's products are subject to third-party testing. We hope you can become one of our good customers. Please feel free to contact us.

PACKING AND SHIPPING

In order for the products to arrive safely, we choose sturdy sea-resistant packaging or according to your needs. Professional and sturdy packaging to protect plates, coils, profiles, bars, pipes, wire rods etc. to the greatest extent and avoid bumps and scratches during transportation.

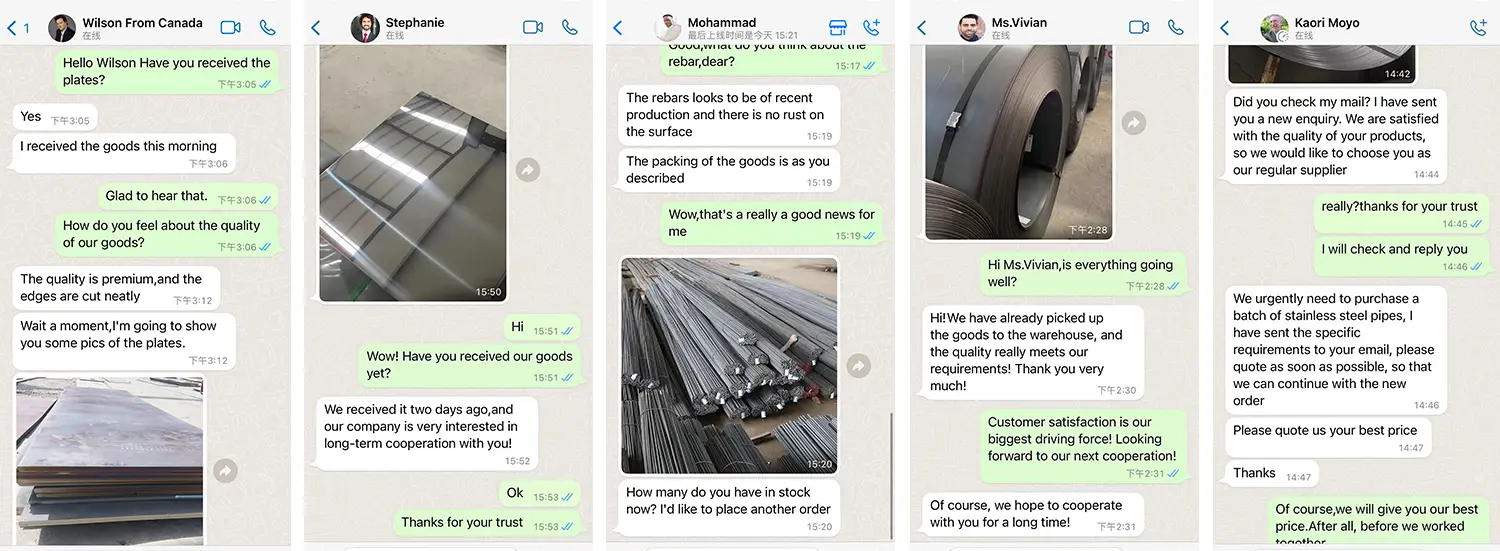

CUSTOMER FEEDBACK

We can provide one-stop services, including transportation, customs clearance and insurance, so that you can handle logistics matters more easily.

Products that are being sold at low prices We will deal with a batch of extruded inventory at ultra-low prices from time to time. The products we deal with include steel pipes, steel plates, round bars, steel bars, steel coils, profiles, rails, wires, etc. Our purpose in dealing with inventory at low prices is to quickly monetize the goods for our daily expenses of steel production. Low-priced products are given priority to regular customers. If you are interested in low-priced steel, please contact us quickly.