![[content:title]](/static/upload/image/20241017/1729148174937375.jpg)

Widely used in petroleum, chemical, power station, boiler and other industries. It is used to make reactors, heat exchangers, separators, liquefied gas tanks, nuclear reactor pressure shells, boiler drum, liquefied petroleum gas cylinders, high-pressure water pipes of hydropower stations, water turbine vortexes and other equipment and components.

1. American container plate:

- SA516Gr60:

- Chemical composition: There are certain requirements for carbon content. Generally, it is within a certain range (the specific value may slightly vary depending on the standard version. Generally, the carbon content is moderate), and the silicon content, manganese content, etc. are also within specific proportional ranges. For example, silicon is roughly within a certain proportional range, and the manganese content also has corresponding regulations.

- Performance data: It has good high-temperature oxidation resistance and certain corrosion resistance, with high strength and can withstand certain pressure and stress. Mechanical property indicators such as tensile strength and yield strength meet the requirements of pressure vessel manufacturing. For example, the tensile strength may be within a certain range, and the yield strength also has a corresponding standard value.

- Uses: Widely used in the manufacture of pressure vessels and pipelines in fields such as petroleum, chemical industry, and nuclear power plants. In these fields, container plates are required to be able to withstand harsh working conditions such as high temperature, high pressure, and corrosive media. SA516Gr60 can meet these requirements and ensure the safe operation of equipment.

- SA516Gr70:

- Chemical composition: The carbon content may be slightly different from that of SA516Gr60, but it is also mainly composed of elements such as carbon, silicon, and manganese. The content ratios of each element are strictly designed and controlled to ensure the performance of the steel plate.

- Performance data: It is a carbon steel plate for low-temperature pressure vessels and has good low-temperature toughness and can maintain good mechanical properties at low temperatures. At the same time, it has high strength and good weldability, which is convenient for processing and manufacturing. For example, its tensile strength, yield strength and other indicators are relatively high and can meet the material strength requirements of large pressure vessels.

- Uses: Commonly used in industries such as petroleum, chemical industry, power stations, and boilers. It can be used to manufacture equipment and components such as reactors, heat exchangers, separators, spherical tanks, gas tanks, liquefied gas tanks, nuclear reactor pressure shells, boiler drums, liquefied petroleum gas cylinders, and high-pressure water pipes for hydropower stations and turbine volutes.

- SA387Gr11CL2:

- Chemical composition: It contains a certain amount of alloy elements such as chromium and molybdenum. The content of elements such as carbon, silicon, and manganese is also within a specific range. The reasonable combination of these elements makes the steel plate have good high-temperature performance and corrosion resistance.

- Performance data: It has high temperature resistance and good strength, and can maintain good mechanical property stability at high temperatures. Its tensile strength, yield strength and other indicators are relatively high and can meet the use requirements of high-temperature pressure vessels.

- Uses: Suitable for refining and gas treatment in hydrogenation reaction and conversion equipment at high temperatures. Widely used in industries such as petroleum, chemical industry, power stations, and boilers. It is used to manufacture equipment and components such as reactors, heat exchangers, separators, spherical tanks, oil and gas tanks, liquefied gas tanks, nuclear reactor pressure shells, and boiler drums.

- SA387Gr91:

- Chemical composition: It contains multiple alloy elements such as chromium, molybdenum, and vanadium. The content of elements such as carbon, silicon, and manganese is precisely controlled. For example, the carbon content is between 0.08 - 0.12%, and the chromium content is between 8.0 - 9.5%.

- Performance data: It has high oxidation resistance and high-temperature steam corrosion resistance. It has the properties of preventing hydrogen embrittlement, hydrogen corrosion, hydrogen exfoliation, and sulfide corrosion in the medium temperature (350 - 480℃) hydrogen-rich environment. At the same time, it has good low tempering brittleness and low-temperature impact toughness. Its tensile strength is ≥585MPa, yield strength is ≥415MPa, and elongation is ≥20%.

- Uses: It can be used as a steel tube for high-temperature superheaters and reheaters with a wall temperature of ≤625℃ in subcritical and supercritical boilers. It can also be used for high-temperature headers and steam pipelines with a wall temperature of ≤600℃. It can also be used for nuclear power heat exchangers and furnace tubes of petroleum cracking units. It is often used in the manufacture of equipment in chemical manufacturing, petrochemical and thermal power plants, such as synthetic ammonia reactors, coal gasifiers, reformers and hydrogenation reactors. It can also be used to manufacture equipment resistant to sulfuric acid, phosphoric acid, formic acid and acetic acid.

2. German container plate:

- 19Mn6:

- Chemical composition: The carbon content is moderate, and the manganese content is relatively high, around 17 - 25%. The content of elements such as silicon, sulfur, and phosphorus is also strictly controlled within a certain range.

- Performance data: It has good mechanical properties at room temperature and high temperatures. The tensile strength is between 350 - 630MPa, the yield strength is between 185 - 310MPa, and the elongation is between 17 - 25%. It has good oxidation resistance and alkaline corrosion resistance, and sufficient creep strength and creep fracture ductility.

- Uses: Mainly used for the manufacture of power station boiler drum reels, which can operate stably for a long time in high-temperature and high-pressure environments.

3. European container plate:

- 13CrMo4-5:

- Chemical composition: The carbon content is between 0.08 - 0.18%, the silicon content is ≤0.35%, the manganese content is between 0.4 - 1%, the chromium content is 0.7 - 1.15%, the molybdenum content is 0.4 - 0.6%, and it also contains a small amount of elements such as copper and nitrogen.

- Performance data: It has high strength and good toughness, and has good heat resistance and corrosion resistance at high temperatures. For example, the impact energy at 20℃ is ≥31J, the tensile strength is between 610 - 780MPa, and the yield strength is ≥290MPa (slightly different for steel plates of different thicknesses).

- Uses: Applied in industries such as petroleum, chemical industry, power stations, and boilers. It is used to manufacture equipment and components such as reactors, heat exchangers, separators, spherical tanks, oil and gas tanks, liquefied gas tanks, nuclear reactor pressure shells, boiler drums, liquefied petroleum gas cylinders, high-pressure water pipes for hydropower stations, and turbine volutes.

4. Japanese container plate:

- SB410:

- Chemical composition: It mainly contains elements such as carbon, silicon, manganese, sulfur, and phosphorus. The content of each element complies with the regulations of Japanese industrial standards. For example, the carbon content is generally within a certain proportional range, and the content of silicon and manganese is also controlled according to the performance requirements of the material.

- Performance data: It has certain strength and toughness and can meet the use requirements of general pressure vessels. Its mechanical property indicators such as tensile strength and yield strength comply with the standards of Japanese container plates.

- Uses: Commonly used in the pressure vessel manufacturing of industries such as petroleum, chemical industry, and machinery manufacturing in Japan. Some are also exported to other countries and regions.

QUALITY INSPECTION

QUALITY INSPECTION

We have won many stable customers with our excellent quality and good service. The company's products are subject to third-party testing. We hope you can become one of our good customers. Please feel free to contact us.

PACKING AND SHIPPING

In order for the products to arrive safely, we choose sturdy sea-resistant packaging or according to your needs. Professional and sturdy packaging to protect plates, coils, profiles, bars, pipes, wire rods etc. to the greatest extent and avoid bumps and scratches during transportation.

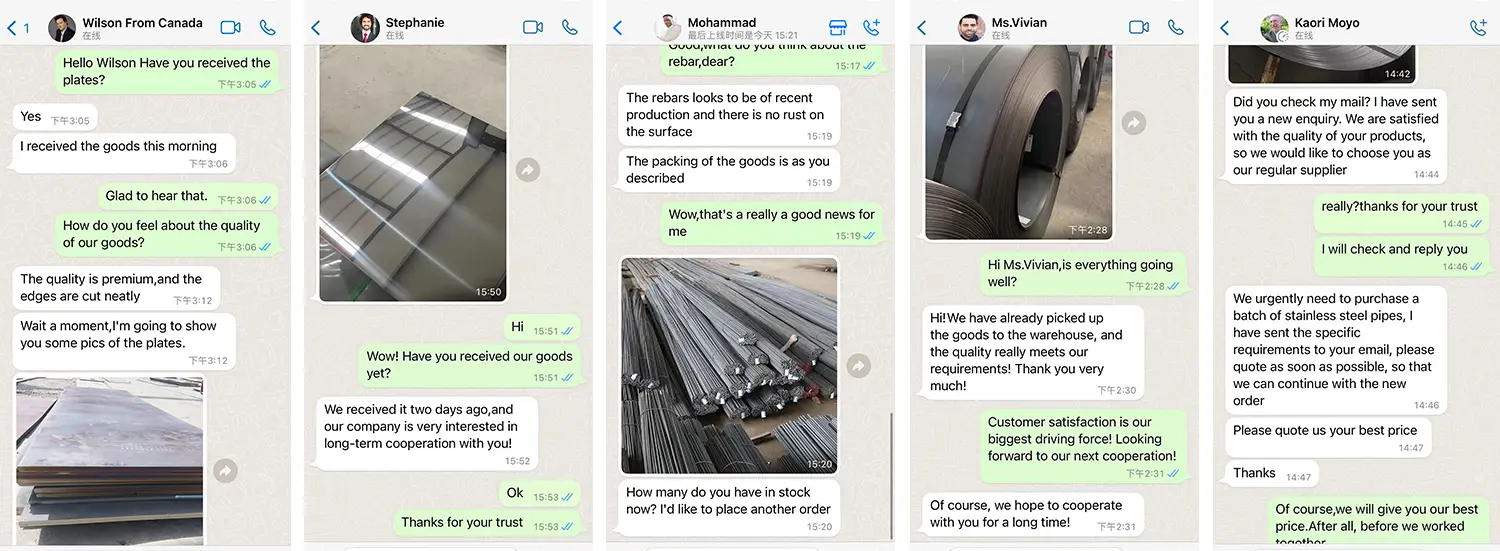

CUSTOMER FEEDBACK

We can provide one-stop services, including transportation, customs clearance and insurance, so that you can handle logistics matters more easily.

Products that are being sold at low prices We will deal with a batch of extruded inventory at ultra-low prices from time to time. The products we deal with include steel pipes, steel plates, round bars, steel bars, steel coils, profiles, rails, wires, etc. Our purpose in dealing with inventory at low prices is to quickly monetize the goods for our daily expenses of steel production. Low-priced products are given priority to regular customers. If you are interested in low-priced steel, please contact us quickly.

Products that are being sold at low prices We will deal with a batch of extruded inventory at ultra-low prices from time to time. The products we deal with include steel pipes, steel plates, round bars, steel bars, steel coils, profiles, rails, wires, etc. Our purpose in dealing with inventory at low prices is to quickly monetize the goods for our daily expenses of steel production. Low-priced products are given priority to regular customers. If you are interested in low-priced steel, please contact us quickly.